|

الحصول على الخاص بك الثالوث الصوت اللاعب جاهز...

|

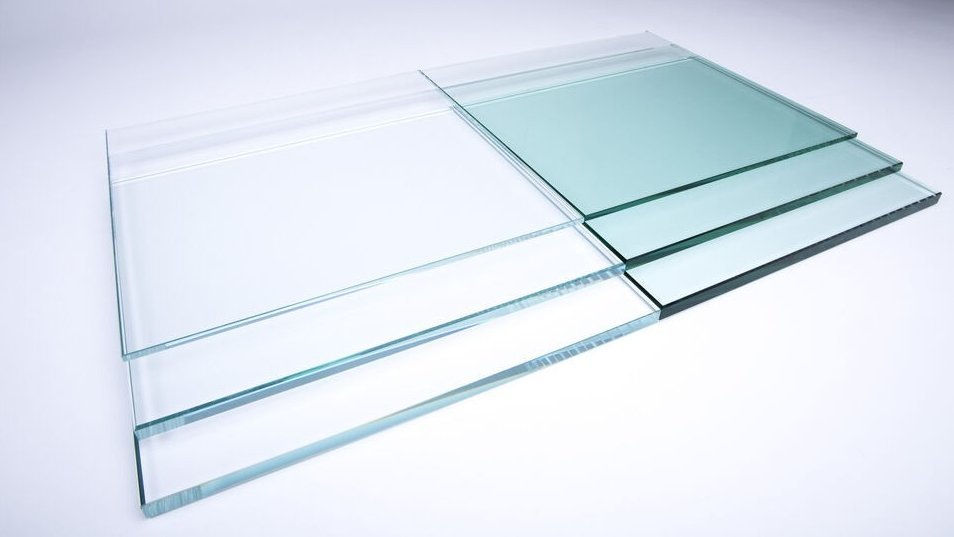

يعد الزجاج المنخفض الحديد والزجاج الشفاف من الخيارات الشائعة في الهندسة المعمارية والتصميم الداخلي, ولكل منهم خصائصه الخاصة. مدى فهم الاختلافات بينهما? To ensure the best results in terms of aesthetics and functionality.

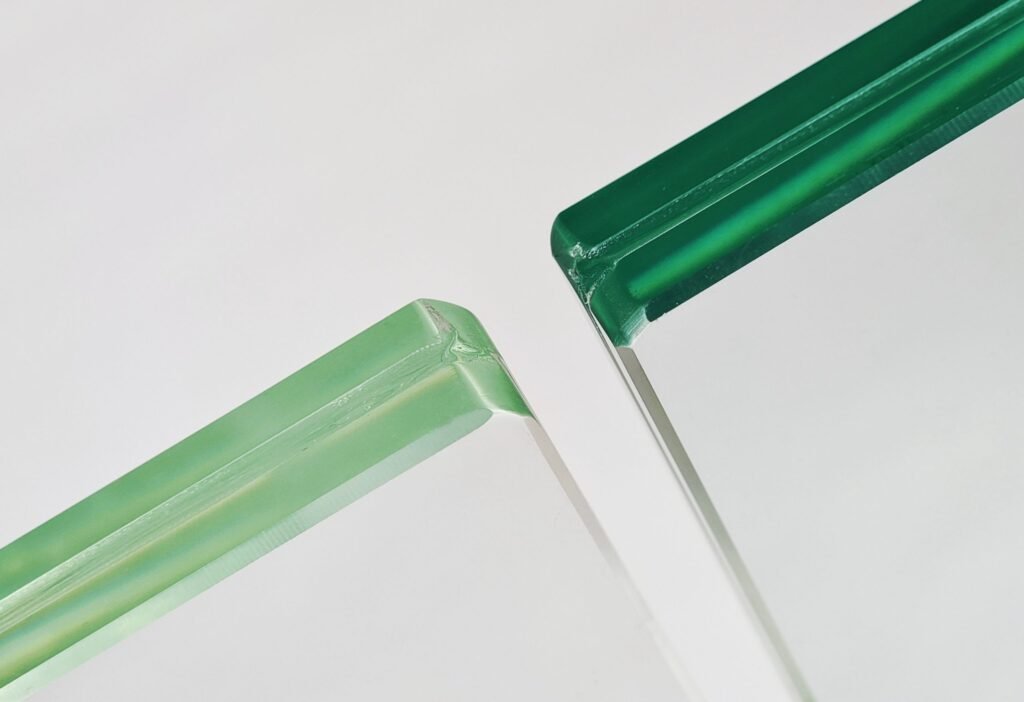

The main difference between low iron glass and clear glass lies in iron content. Low iron glass features reduced iron impurities, resulting in higher transparency and a neutral appearance. في المقابل, clear glass often has a slight green tint, which becomes more pronounced with increased thickness.

الآن, we will explore how low iron glass and clear glass compare in terms of strength, cost, applications, and other key attributes.

What is Low Iron Glass?

Low iron glass is a type of glass manufactured to minimize the iron content present in the raw materials. This reduced iron content results in a highly transparent, color-neutral material. The glass appears almost completely clear, without the greenish hue typically associated with standard clear glass.

Low iron glass boasts unparalleled light transmission rates of up to 91-92% compared to the approximately 83-87% transmission of standard glass (Pilkington). This property makes it ideal for use in environments where accurate color rendition and maximum brightness are essential, such as high-end مرايا مضاءة produced by led mirror factories and architectural facades.

What is Clear Glass?

Clear glass, commonly known as float glass, is a standard type of glass used in windows, doors, and everyday products. It is manufactured with raw materials containing iron, which imparts a subtle green tint, particularly noticeable in thicker panes.

Clear glass is an economical option and is widely used due to its cost-effectiveness and versatility. لكن, its greenish tint can impact the appearance of items behind the glass, making it less suitable for applications where true color representation is essential. Bathroom mirror manufacturers might opt for clear glass for basic, budget-friendly mirrors but lean towards low iron glass for premium products.

Is Low Iron Glass Stronger than Clear Glass?

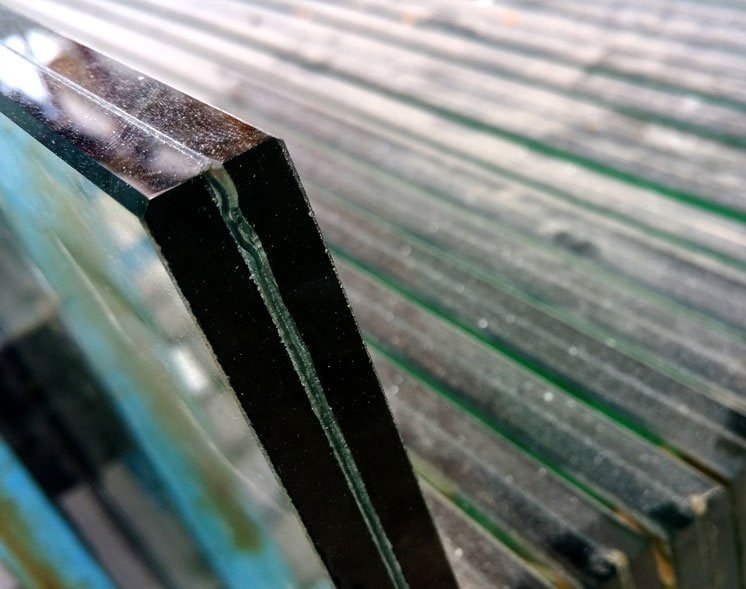

A common question is whether low iron glass is inherently stronger than clear glass. Both types of glass have comparable strength, with durability largely determined by the thickness and tempering process. According to industry reports, tempered glass, whether low iron or clear, can be up to four times stronger than untreated glass.

For manufacturers in the مصنع مرآة الصمام business, tempered low iron glass provides the dual benefit of safety and superior aesthetics. The choice of low iron glass in high-end projects is more for its visual qualities than for any significant difference in strength.

Is Low-Iron Shower Glass Worth It?

Low iron glass has become a sought-after choice for modern, luxurious bathroom designs. Low-iron shower glass provides a clear, color-neutral look, eliminating the greenish tint that standard glass often displays. This clarity makes bathrooms feel more open and brighter, which is especially desirable in high-end home construction and hotel settings.

Research from the design industry highlights that spaces with greater natural light and clarity are perceived as larger and more inviting. لهذه الأسباب, many homeowners and developers find low iron glass worth the added investment, especially in upscale renovations where visual impact matters.

What is the Advantage of Low Iron Glass?

The key advantage of low iron glass is its superior clarity. With higher light transmission and true color representation, it ensures that objects viewed through the glass retain their original color and sharpness. This benefit is why الشركات المصنعة مرآة الحمام and other high-end producers prefer low iron glass for applications requiring visual accuracy and luxury appeal.

Projects involving مرايا مضاءة particularly benefit, as the low iron glass eliminates color distortion, providing more vivid and lifelike reflections.

How to Tell if Glass is Low-Iron?

A simple way to distinguish low iron glass from regular clear glass is to observe the glass from the side. Low iron glass will appear nearly colorless or with only a faint tint, while standard clear glass has a more pronounced green hue due to its higher iron content.

Testing glass quality through visual checks is crucial for مصنع مرآة الصمام assessments and quality assurance. Such tests ensure that buyers receive the material they need for their specific applications.

What is the Clearest Glass Called?

The clearest type of glass is known as low iron glass, also referred to as ultra-clear glass or opti-white glass. It offers unmatched transparency, making it the preferred material for applications that require an unblemished view or true-to-life reflections.

Its use in luxury interior design, display cases, and architectural facades is due to its ability to let maximum light pass through without color alteration. This type of glass is a key choice for مرايا مضاءة that demand pristine clarity.

Is Low-Iron Glass More Expensive?

نعم, low iron glass generally comes at a higher cost compared to standard clear glass. This is due to the specialized manufacturing process that removes iron impurities, enhancing its clarity and visual appeal. According to data from market analyses, low iron glass can be up to 30-40% more expensive than clear glass.

ل الشركات المصنعة مرآة الحمام و led mirror factories, investing in low iron glass is justified for projects that require the best possible visual output and client satisfaction.

What is Another Name for Low-Iron Glass?

Low iron glass is also known by various names, such as ultra-clear glass, starphire glass, or opti-white glass. These names emphasize its exceptional transparency, which distinguishes it from other types of glass.

Familiarity with these alternative terms can help professionals and buyers navigate product options more easily, ensuring they select the right material for their projects.

What is the Cleanest Glass in the World?

Low iron glass is considered one of the cleanest glasses available due to its high level of transparency. With minimal impurities and a nearly colorless appearance, it is perfect for applications requiring clarity, such as museum displays, jewelry showcases, and premium home mirrors.

في مصنع مرآة الصمام settings, this type of glass ensures that lighted mirrors are free from color distortions and maintain a high-end look.

Is Low E the Same as Low Iron?

لا, low E (low emissivity) glass and low iron glass serve different purposes. Low E glass is designed to improve energy efficiency by reducing heat transfer, making it suitable for windows and glazing that need to minimize thermal loss. على الجانب الآخر, low iron glass focuses on enhancing clarity and color accuracy.

Both types of glass have their place in modern architecture, but they fulfill distinct roles. Low E glass is valued for sustainability and thermal insulation, while الشركات المصنعة مرآة الحمام often choose low iron glass for its superior visual properties.

What Brands Are Low-Iron Glass?

Several leading brands manufacture high-quality low iron glass, each known for their innovation, متانة, and exceptional transparency. Saint-Gobain, على سبيل المثال, produces “Diamant,” a premium low iron glass renowned for its impressive clarity and minimal green tint. This product is widely used in luxury architectural projects, display cases, و مرايا مضاءة made by top-tier led mirror factories.

Pilkington, a well-respected name in the glass industry, offers “Optiwhite,” a low iron glass that boasts up to 91% light transmission. This ensures objects behind the glass maintain true color representation, making it a preferred choice for applications requiring high aesthetic standards.

Guardian Glass markets its low iron option as “UltraClear.” Known for its consistent quality and color-neutral appearance, UltraClear is frequently used in high-end residential and commercial buildings where visual impact is critical. ل الشركات المصنعة مرآة الحمام and those involved in producing مرايا مضاءة, choosing from these brands means committing to quality that enhances their products’ appeal and performance.

Does Low-Iron Glass Have a Green Edge?

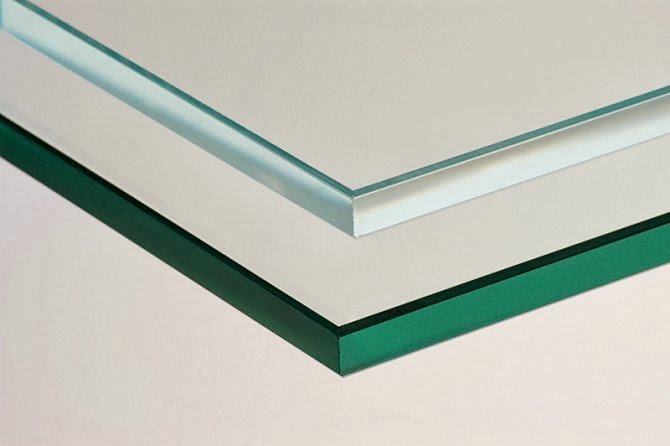

One of the standout features of low iron glass is its edge clarity. Unlike standard clear glass, which typically has a visible green tint along the edges, low iron glass appears almost white or colorless at its edges. This is because it contains significantly less iron oxide, the element responsible for the green hue in traditional glass.

This edge clarity provides a seamless look that is particularly desirable in high-end projects where aesthetics matter. على سبيل المثال, architectural designers often choose low iron glass for balustrades, tabletops, و مرايا مضاءة to maintain a crisp, modern appearance without color distortion. This is especially relevant in applications that require transparency from multiple angles, such as frameless glass installations, where the green tint of standard glass would be immediately noticeable and potentially detract from the overall design.

Is Low-Iron Glass Softer?

The perception that low iron glass might be softer than regular clear glass is a common misconception. Both low iron glass and standard clear glass have similar hardness levels because their core material—silica-based glass—is the same. The difference lies in the iron content, which affects the color but not the structural properties.

لكن, both types of glass can be tempered or laminated to increase their hardness and durability. Tempering processes can make glass up to four times stronger than untreated glass, whether it is low iron or standard clear. This is a critical factor for مصنع مرآة الصمام إنتاج, where glass needs to be both aesthetically pleasing and capable of withstanding regular use and handling.

Can You Tell if Your Iron is Low by Your Eyelids?

This question is more relevant to health than the properties of glass, but it’s worth addressing for clarity. Pale or discolored eyelids can indeed be a sign of low iron levels in the body, which might indicate anemia or iron deficiency. This has no connection to the iron content in glass but is rather a health concern that should be assessed by medical professionals.

For those in construction or design, distinguishing between low iron and standard glass is based on visual inspection rather than health indicators. Low iron glass will have clear, neutral edges, while standard glass will display a noticeable greenish tint.

Is Low-Iron Glass Reflective?

نعم, low iron glass can be reflective, but its reflection properties differ slightly from regular glass. Low iron glass produces a clearer and more natural reflection due to its high transparency and minimal color distortion. This makes it ideal for applications like مرايا مضاءة and high-quality furniture where true-to-life reflections are crucial.

In mirrors, the reduced green tint ensures that colors appear as they are, without the subtle shift caused by standard glass. Bathroom mirror manufacturers prefer low iron glass for this reason, as it provides an authentic and sharp reflection, enhancing the user experience. بالإضافة إلى ذلك, coatings can be added to low iron glass to reduce reflectivity if needed, making it a versatile option in both residential and commercial spaces.

Does Low-Iron Glass Have Green Edges?

Low iron glass edges do not have the pronounced green tint characteristic of standard clear glass. The minimal iron content results in edges that appear nearly white, contributing to a cleaner and more visually appealing profile. This is particularly important in design elements where edge visibility plays a significant role, such as in glass partitions, tabletops, and high-end مرايا مضاءة.

For applications where aesthetics are paramount, such as luxury bathrooms and upscale interior designs, the absence of green edges ensures that low iron glass blends seamlessly into its surroundings. This attribute enhances the overall transparency and brightness of a space, making it a preferred choice among architects and designers looking for a refined finish.

How Can I Tell if My Iron is Low?

If you’re asking about iron levels in the human body, the best way to assess low iron is through medical testing. Symptoms such as fatigue, paleness, or cold extremities could indicate low iron levels, but a blood test administered by a healthcare provider will give definitive results. This topic, لكن, is unrelated to low iron glass properties.

When it comes to identifying low iron glass itself, visual inspection is key. Observing the edges of the glass is a straightforward method: low iron glass will have a near-transparent, almost white edge, while standard glass will have a more apparent green tint. This simple test helps in selecting the appropriate glass type for specific projects, whether it be for architectural purposes or the production of المرايا LED.

خاتمة

Understanding the differences between low iron glass and clear glass helps you make informed decisions based on your project’s needs. ل الشركات المصنعة مرآة الحمام, luxury interior projects, و led mirror factories, low iron glass offers unparalleled clarity and true color transmission. While clear glass serves as a cost-effective solution for many applications, the choice should align with desired aesthetics and project budgets.