Cutting Mirror is the first step, usually, we will cut a few millimeters more, This is to ensure that there will not be too much loss in the subsequent edging process, which will lead to the discrepancy between the finished product size and the order.

The effect of edging is made the mirror’s edge becomes smooth, making sure the mirror won’t hurt the customer’s hands. meanwhile, this step is to get prepare for the subsequent operation.

Paste protective film is used to protect the surface of the mirror from damage in the transport, at the same time, it also good for the next step.

Cutting Mirror is the first step, usually, we will cut a few millimeters more, This is to ensure that there will not be too much loss in the subsequent edging process, which will lead to the discrepancy between the finished product size and the order.

The effect of edging is made the mirror’s edge becomes smooth, making sure the mirror won’t hurt the customer’s hands. meanwhile, this step is to get prepare for the subsequent operation.

Paste protective film is used to protect the surface of the mirror from damage in the transport, at the same time, it also good for the next step.

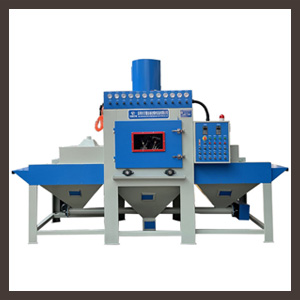

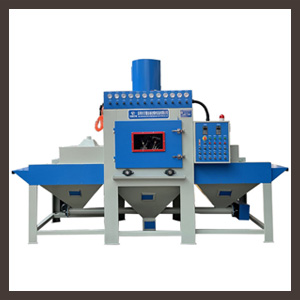

Girt blast is a important step for all the led mirrors,If we do not take the sand blasting step,then led light will not have shining forward through the mirror.

This step is print your logo on the mirror, which is an important part of customizing the mirror,meanwhile we can print some patterns for decoration.

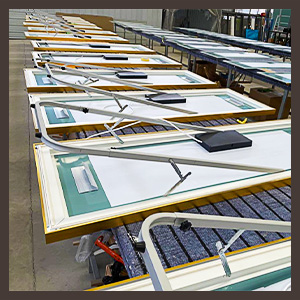

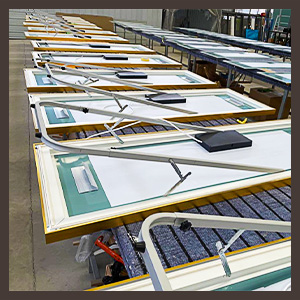

mainly assembling a led mirror including installing switches, back frames, light strips, and power supply, Here we realize the combination of soul and body. a led mirror came to this world.

Girt blast is a important step for all the led mirrors,If we do not take the sand blasting step,then led light will not have shining forward through the mirror.

This step is print your logo on the mirror, which is an important part of customizing the mirror,meanwhile we can print some patterns for decoration.

mainly assembling a led mirror including installing switches, back frames, light strips, and power supply, Here we realize the combination of soul and body. a led mirror came to this world.

Each product need past test before delivery,such as,72 hour power on test, The last mirror bubble test and safety packaging test,make sure every single product are complete and perfect.

For the package,we mainly use PE bag + all around EPS foam + Inner carton + out carton, 1 pcs/ctn; Wooden Case / Pallet optional,those package are strong are tight to protect your goods.

Each product need past test before delivery,such as,72 hour power on test, The last mirror bubble test and safety packaging test,make sure every single product are complete and perfect.

For the package,we mainly use PE bag + all around EPS foam + Inner carton + out carton, 1 pcs/ctn; Wooden Case / Pallet optional,those package are strong are tight to protect your goods.

This is the last step,your led mirror and mirror cabinet are can’t wait to your hands,and they are strong enough to across the ocean.

Send your request now. Our experienced team will reply you within 8 working hours.

Send Us Message

Please fill out the form below and we will send it to your email address if the download is unsuccessful.