|

Getting your Trinity Audio player ready...

|

Mirrors are an integral part of everyday life and are found in bathrooms, bedrooms and cars. But have you ever wondered how are mirrors made?

First, using ordinary glass as raw material, a mixture of polishing powder and water is used for the grinding and polishing process. After that, the surface of the glass is cleaned with a high-pressure water gun, and then a layer of silver is plated on the back of the glass. In the subsequent inspection session, the main focus is to check the light transmission and surface quality of the mirror to ensure that there are no scratches, bubbles and no chipping at the edges.

Finally, the mirrors are cut into specific shapes as needed and the edges are polished and sanded to meet customer requirements. In addition to the traditional silver mirrors, there are also mirrors using cheaper backside aluminized mirrors. These aluminum mirrors are made in a vacuum so that the aluminum evaporates and condenses on the glass surface to form an aluminum film, which is less costly and has a good light-harvesting effect.

Now that we’ve set the stage, let’s dive into the various stages of mirror manufacturing.

The Raw Materials: Glass and Silvering

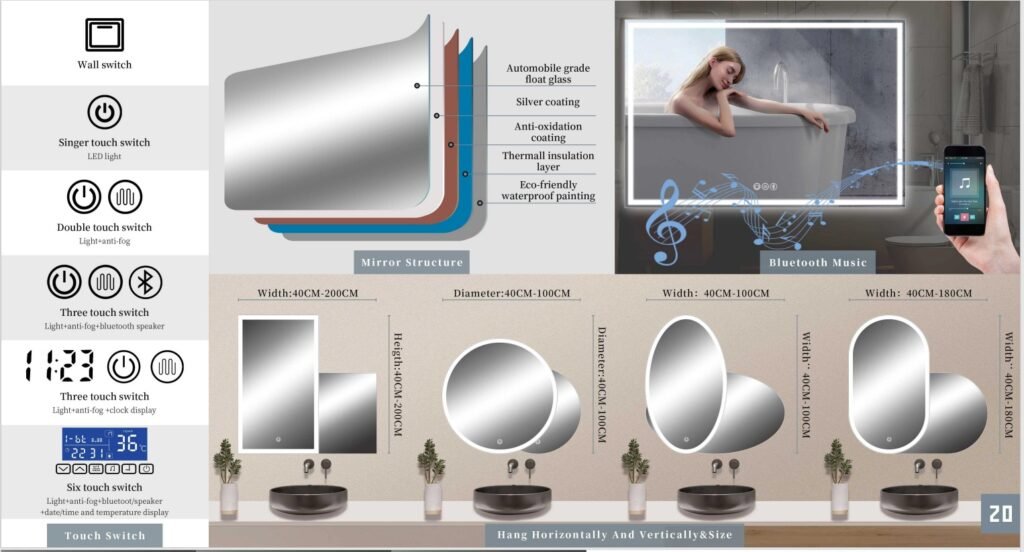

The process of making a mirror begins with raw materials. Most mirrors are made from glass, which is a common material due to its clarity and ease of processing. The first step is to cut the glass to the desired size, followed by cleaning it thoroughly. Once the glass is prepped, it is coated with a reflective material, typically silver or aluminum.

The glass is the most important part of a mirror, but the reflective surface is made of metals like silver or aluminum. The type of metal used for the reflective surface can affect the quality of the reflection and the life of the mirror.

The first raw material is glass. In most cases, float glass is used because it has a smooth, even surface that is perfect for the reflective layer. The glass is cleaned thoroughly to remove any dirt, oils, or impurities. Once cleaned, a thin layer of silver or aluminum is applied to the glass, creating the reflective surface.

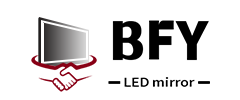

This silvering process, which involves a chemical reaction, allows the mirror to reflect light and produce a clear image. Some mirrors, like personalised LED mirrors, might also have additional features like color-changing light or fog resistance, but the basic process remains the same.

The Silvering Process: Coating the Glass

After the glass is prepared, the next critical step is silvering. This is the process of applying a reflective metal layer, usually silver or aluminum, to the back of the glass. This layer is what gives the mirror its reflective properties and allows us to see our reflection clearly.

Silvering is the process of applying a thin metallic layer to the glass to create the reflective surface. The most common metals used in this process are silver and aluminum.

In traditional mirror-making, silver is applied to the surface of the glass by using a solution of silver nitrate and ammonia. The chemical reaction between the silver nitrate and ammonia creates a silver film that bonds to the glass, creating a mirror-like finish. Aluminum is also used, especially in mass-produced mirrors, because it is less expensive and more durable. In high-end mirrors, such as custom LED mirrors, the silvering process is carefully controlled to ensure a high-quality, flawless finish.

Adding Protection: Backing and Coating

Once the reflective layer is applied, the mirror’s surface needs to be protected. This is done by applying a backing, which helps to hold the reflective layer in place and keep it from being damaged. A protective coating is then applied to maintain the quality of the mirror.

Mirrors are backed with materials like copper or paint to protect the reflective surface and enhance the mirror’s longevity.

The silver or aluminum coating that is applied to the glass is very delicate and can be easily scratched. To protect the reflective layer, a backing material is applied to the mirror. Copper is often used because it provides extra protection and helps to make the reflective surface more durable.

Once the copper backing is applied, a layer of paint or lacquer is added to keep the mirror from deteriorating and to prevent oxidation over time. In more advanced models, such as personalized LED mirrors, additional coatings may be added to increase functionality, such as water resistance or light diffusion.

Cutting, Polishing, and Edge Finishing

Once the mirror has been silvered and backed, it is cut to size and the edges are polished to remove any sharp corners. This ensures that the mirror is safe for handling and has an aesthetically pleasing finish.

After the mirror is backed and coated, it is cut to the desired dimensions, and the edges are smoothed and polished for safety and visual appeal.

The mirror is cut to size with a machine that is dead-on accurate, so the mirror fits perfectly where you want to put it (in your bathroom or on top of your vanity). Then the edges are smoothed and polished so you don’t cut yourself.

In some cases, mirrors are given beveled edges or decorative framing for a more refined look. For high-end mirrors like those offered by bathroom mirror manufacturers, extra attention is paid to the finishing, as this can significantly impact the overall look and feel of the mirror in your space.

Quality Control and Final Inspection

Before we ship it to you, we do a final quality control check to make sure that mirror is perfect, that it’s clear, that it’s reflective, and that it’s going to last.

Quality control ensures that every mirror meets the desired standards of reflectivity, clarity, and overall quality before being shipped.

The mirror goes through quality control when the reflective coating is applied. They check to make sure there are no flaws in the mirror’s clarity and reflectivity. They test to make sure the mirror is durable and won’t easily be damaged.

Any mirror that doesn’t meet our high standards is thrown away or sent back to be reworked. This is especially important with high-end products like custom LED mirrors because people expect a perfect, high-quality finish. Once the mirror passes quality control, we package it up carefully and ship it to you.

FAQS

What Are Mirrors Made Of?

Mirrors are made of glass, but the reflective surface is made of stuff like silver, aluminum, or sometimes chrome. Most mirrors are made by putting a reflective metallic coating, like silver or aluminum, on the back of a piece of glass.

The most common base material is glass, but mirrors can also be made from other materials like acrylic or plastic, depending on the application. The reflective surface is usually created by putting a thin layer of silver or aluminum on the back of the glass. The material used for the reflective surface can affect the quality of the reflection. Silver, for example, provides a brighter reflection but is more prone to tarnishing. Aluminum is less bright, but it’s more durable.

How Are Mirrors Made? The Step-by-Step Process

Making a mirror involves several steps: preparing the glass, applying the reflective coating, backing the mirror, cutting and finishing, and finally, inspecting the mirror for quality. Mirrors are created through a multi-step process that includes glass preparation, silvering, backing, cutting, and final inspection.

The process starts with cutting and cleaning the glass, then silvering or applying aluminum. Once the reflective coating is applied, the mirror is backed with a protective layer and painted to prevent damage.

The mirror is then cut to size, the edges are polished, and the mirror undergoes a final quality check before it is shipped. This multi-step process ensures that every mirror is durable, high-quality, and ready for use in homes, bathrooms, and commercial spaces.

How Are Mirrors Created?

Mirrors are made through a series of carefully controlled processes. It starts with the selection of materials and ends with a final quality inspection.

Making a mirror involves several key steps: material selection, silvering, backing, and finishing, all designed to produce a high-quality reflective surface.

Making a mirror is a complicated process that involves careful selection of materials like glass and metal. The glass is treated to ensure smoothness, then coated with a reflective metal, either silver or aluminum, using chemical reactions.

After the reflective layer is applied, a protective coating is added to preserve the mirror’s longevity. The mirror is then cut to size, edges are smoothed, and a final inspection ensures it meets quality standards before being packaged and shipped.

What Material is Used to Make a Mirror?

The most common material used for the reflective coating is metal, such as silver, aluminum, or chromium.

A mirror is made of glass and coated with metals such as silver or aluminum to create the reflective surface. The material you choose determines how long it will last and how much it will cost.

In the past, silver was the metal of choice, but because of cost and availability, aluminum is now used most often. Both metals are durable and provide excellent reflectivity, but aluminum is less likely to tarnish.

How is a Mirror Made from Sand?

Mirrors start with the most basic element: sand. Sand is refined into glass, the primary material in mirror production.

To make glass, sand is heated to a very high temperature until it melts and becomes liquid glass. The liquid glass is then cooled, cut into sheets, cleaned, and polished. The reflective coating is applied last, making the glass a mirror.

How Are Mirrors Made Step by Step?

The process of making a mirror involves several key stages, from preparing the glass to adding the reflective coating and protective layers. Here are the steps to make a mirror: 1. Cut the glass 2. Apply a reflective metal layer 3. Apply a protective backing 4. Polish the edges 5. Final inspection

The glass is cut to the required size. A reflective metal layer (usually silver or aluminum) is applied using a chemical process. The mirror is then backed with copper or another protective material. The edges are polished, and a final quality check is performed before the mirror is shipped.

How Are Mirrors Made for Kids?

Mirrors for kids are made the same way as regular mirrors, but they often have added safety features and colorful frames. The materials are the same, but the mirrors are often kid-friendly with rounded edges and colorful designs.

In the case of children’s mirrors, they make sure the edges are rounded so kids won’t hurt themselves. The reflective quality is the same, but the design might include fun colors or shapes to appeal to children. The glass and coatings are non-toxic and meet safety standards for children.

Mirror is Made Up of Which Metal?

Mirrors are made using metals like silver, aluminum, and sometimes chromium to form the reflective coating on glass. Silver and aluminum are the most common metals used to create the reflective coating on mirrors.

The reflective layer in mirrors is typically made from silver or aluminum, with silver being the traditional choice. However, aluminum is often preferred in modern mirrors due to its resistance to tarnishing and its cost-effectiveness.

How Are Mirrors Made to Reflect?

Mirrors reflect light due to a thin metal coating applied to the glass surface. This layer allows light to bounce off, creating the reflection we see. A reflective coating on the mirror’s surface bounces light off, creating the image we see.

The reflective properties of a mirror come from the metal layer applied during the silvering process. Silver or aluminum reflects light, and when light hits the surface, it bounces back in a way that creates a clear reflection.

When Did They Stop Using Mercury in Mirrors?

Historically, mercury was used in mirror-making, but due to health and environmental concerns, it has largely been replaced by other materials. Mercury was once used in mirror production, but it was phased out due to safety and environmental concerns, replaced by silver and aluminum.

Mercury was used in the silvering process of mirrors up until the 19th century. However, as awareness of mercury’s toxic effects grew, the practice was abandoned. Today, silver and aluminum are the most commonly used metals for mirror production.

How Were Mirrors Made in the Past?

In ancient times, mirrors were made from polished stone, metals, and even water. Early mirrors were made from polished metal or stone, and the process evolved as glass became more widely available.

Early civilizations used polished metals like bronze, copper, and silver, as well as polished stones such as obsidian. These primitive mirrors had limited reflective properties, but they were used for centuries before the advent of glass mirrors.

What Were Mirrors Originally Made Of?

The earliest mirrors were crafted from polished metal, stone, and even water. Early mirrors were often made from highly polished metal or stone. Glass mirrors became widespread much later in history.

Before glass, people used reflective surfaces like polished metal, obsidian, and even still water to see their reflections. These primitive mirrors had limited clarity and reflectivity compared to modern mirrors.

Are Mirrors Plastic or Glass?

Mirrors are typically made of glass, but some may use plastic or acrylic as a lighter, less fragile alternative. While glass is most common, mirrors can also be made from plastic or acrylic, which is more durable and lightweight.

Glass remains the primary material for mirrors due to its clarity and reflective quality. However, for safety reasons or cost-effectiveness, some mirrors, particularly those in children’s products or low-cost models, may be made from plastic or acrylic.

How Were Mirrors Made in the 1800s?

In the 1800s, mirrors were made using silvering techniques with mercury, which was later replaced due to safety concerns. During the 1800s, silvering mirrors with mercury was a common method, although it was eventually phased out due to health risks.

In the 1800s, the process of creating mirrors involved applying a layer of mercury and silver to the glass. This method was highly effective but also hazardous, leading to the eventual transition to safer methods using silver or aluminum.

How Were Mirrors Made in the 1700s?

In the 1700s, mirrors were typically made by applying a layer of mercury and silver to glass, similar to the 1800s. In the 1700s, silvering mirrors with mercury was the primary technique for creating reflective surfaces.

Mirrors in the 1700s were often created by applying mercury and silver to glass, a method that was refined during this time. This technique allowed for clear, reflective surfaces, although it posed serious health risks.

Conclusion

Understanding how mirrors are made provides insight into the careful craftsmanship and technology that goes into producing every reflective surface. Whether you’re purchasing a custom LED mirror for your bathroom or a simple wall mirror, knowing the manufacturing process can help you choose a high-quality product. From glass and metal coatings to the final finishing touches, mirrors are much more than just a reflective surface—they are a product of meticulous design and manufacturing expertise.